Litz wire, magnet wire, ferrite toroids

I then found that the coupling transformer was getting hot. It got so hot the wire started melting though the insulation. I switched the toroid from the powered iron to a 3C90 ferrite toroid core. I use 4 1" thick x 2.5" OD x 1.5" ID toroids. I got them from Ferroxcube. The part number for the 3C90 material is TC25151. The high permeability ferrite and the number of them assures me there will be no core heating or saturation. The wire is #10 and I use about 20 turns. I found that at lower turns the primary current was too high. By adding more turns, I needed more primary voltage, but I used less current. I then mounted a dedicated 100cfm fan for cooling the transformer.

Right now I am trying ferrite toroids that are larger to accomodate a thicker gauge of wire. I am using the ZP48613TC toroids from Magnetics. They are about 4" x 3" x 1/2". I am using seven of them to reduce the flux density. They are coated so I don't need to worry about shorting the wire. The wire is made from 23g magnet wire. I have 64 strands (good for 46A of DC current) twisted and braided. This took a little time, but I got it down to make 25' cord in a short period. 100khz should use 26g, but I think the 23g will work out well enough. I don't want to braid several hundred strands. I will go over some flux calculations on the next page.

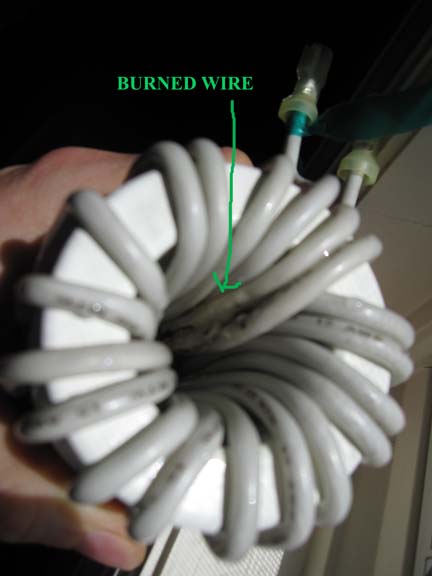

The original primary used 10g wire. This was unable to handle the current, and despite forced convection cooling, overheated and melted the vinyl wire coating.

Below is the braided litz wire that I made from magnet wire

Below is the ferrite toroid wrapped with 26 turns of the magnet wire braid