Induction Heater Tutorial

10kw and 3kw

An induction heater is an interesting device, allowing one to rapidly heat a metal object. With enough power, one can even melt metal. The induction heater works without the need for fossil fuels, and can anneal and heat objects of various shapes. I set out to make an induction heater that could melt steel and aluminum, so I put together a unit that put out about 3 kilowatts! Next, I built a 10kw unit that was able to lock on the resonant frequency all by itself. Both units were capable of levitating metals. This tutorial has a lot of pages filled with practical and theoretical information to aid you in following my endeavor. Just keep clicking next and eventually you will get to the schematics. I have a few of them for the smaller and larger inverters.

*****

Many of you will have questions after reading through this tutorial. For this reason I have put together several playlists on Youtube explaining the finer details of making a reliable induction heater. There are videos showing it working on my channel and videos explaining how to design and make the various parts. A good playlist of mine is ---->here, but there are even more videos on the Imsmoother youtube channel. The videos are well worth your time.

*****

The first part of this tutorial will go through my development of a 3kw inverter. My initial goal was to rapidly heat metals. My next goal was to levitate metals. I succeeded, but realized that I could not levitate solid copper and steel. Their density was too great for the magnetic field. This was my final goal: to levitate and suspend molten copper and steel. At the end of this tutorial I will go into the development of a 10kw unit that realized this goal. I will also elaborate on the problems that had to be overcome in order to achieve this.

Let's start.

My induction heater is an inverter. An inverter takes a DC power source and converts it into AC power. The AC power drives a transformer which is coupled to a series LC tank. The inverter frequency is set to the tank's resonant frequency, allowing the generation of very high currents within the tank's coil. The coil is coupled to the workpiece and sets up eddy currents. These currents, traveling through a conductive, but slightly resistive workpiece, heat the piece. Remember, Power = Heat = R*I^2. The workpiece is like a one-turn coil; the work coils has several turns. Thus, we have a step-down transformer, so even higher currents are generated in the workpiece.

I would like to acknowledge the invaluable help from John Dearmond, Tim Williams, Richie Burnett and other members of the 4hv forum for helping me understand this topic. Now, before we talk more, let's see some pictures of what it can do:

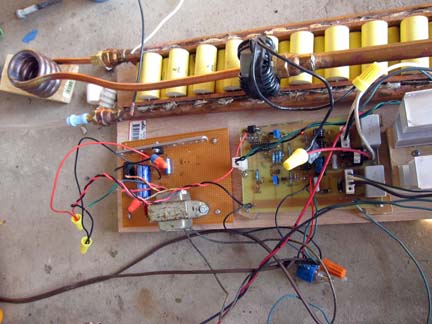

Later, I will give a link to a video showing it running. Here is the inverter:

What I will now do is go over each part. Then, I will give the schematics, go over them and how you can build this device.